In recent years improvements in machine data collection protocols have paved the way for more companies to offer products to the CNC machine monitoring industry. This is both good and bad. It is great to have competition, it makes us all better and forces software developers to improve or step aside. For that reason, we welcome this development. The downside, however, is that many companies that have not invested in a complete product portfolio are winning the low-hanging fruit, the network protocol-based data collection business, and trapping the customer on a technology island. This island is not connected to the rest of the eco-system, there is no awareness between that platform and the communications platform, or the data management platform. This is very much counter to the Industry 4.0/Smart Factories direction industry is moving in. Most of these providers also lack the ability to deliver signals from legacy equipment or even basic solutions for RS-232 based equipment that is common in many manufacturers today.

In recent years improvements in machine data collection protocols have paved the way for more companies to offer products to the CNC machine monitoring industry. This is both good and bad. It is great to have competition, it makes us all better and forces software developers to improve or step aside. For that reason, we welcome this development. The downside, however, is that many companies that have not invested in a complete product portfolio are winning the low-hanging fruit, the network protocol-based data collection business, and trapping the customer on a technology island. This island is not connected to the rest of the eco-system, there is no awareness between that platform and the communications platform, or the data management platform. This is very much counter to the Industry 4.0/Smart Factories direction industry is moving in. Most of these providers also lack the ability to deliver signals from legacy equipment or even basic solutions for RS-232 based equipment that is common in many manufacturers today.

Why Having a Connection to DNC Software is Essential for Machine Data Collection

There are a few huge benefits and unique capabilities for a machine data collection system that is also tightly integrated with the DNC software. Think of DNC as the communications solution for all CNC-based machines of any type, not just machines with an Ethernet connection. Here are a few of the areas DNC matters:

- Accessibility to DPRNT statements for machines with RS-232 options

- The capability of inserting values or manipulation content of NC programs during transmission

- Ability to trigger data collection events during file transfers that would require an operator to perform

DPRNT Statements, Data From the CNC During NC Code Execution

DPRNT statements allow CNC machines equipped with an RS-232 port connected to CIMCO DNC Max to talk back to our system. One example of where this can be used is for an inexpensive and easy to deploy cycle time counter and part counter. A DPRNT statement at the beginning of the program can indicate that the cycle is starting, another one can indicate what program is running, and even another for the number of parts per cycle. Even if you are capturing the cycle time using hardware, these bits of information can greatly enhance the quality of data being collected without forcing an operator to key this information in themselves. Data collection software that only interfaces with specialized hardware or machines with network data collection protocols such as Haas M-Net, FANUC FOCAS, MT-Connect, etc. will not be able to use this method. Since many shops have numerous older RS-232 equipped machines, these providers will not be able to fully service this need. DPRNT is so useful that many of our installers and technicians lament its previous ubiquitous status when connecting new machines that do not have the capability. Ironically, if a machine tool company retained this ability, their equipment would be incredibly flexible and allow for far more Industry 4.0/Smart Factory level integration. This is a case where a legacy to the semi-obsolete system is actually incredibly useful.

Inserting Values into NC-Code When Sending and Much More

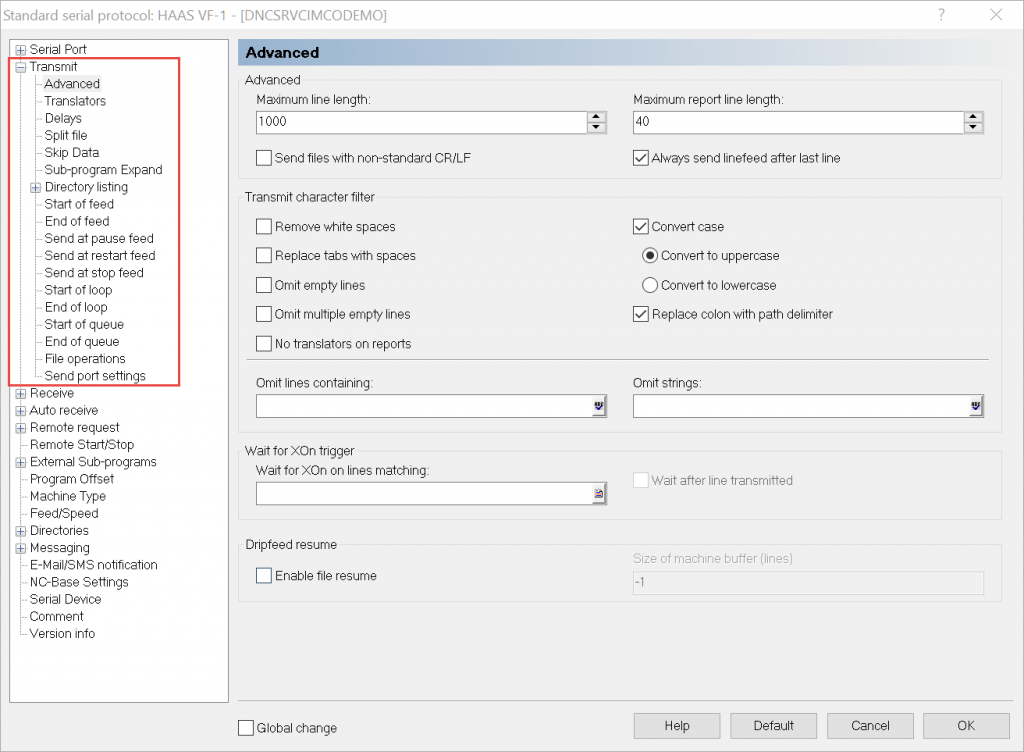

A DNC system like CIMCO DNC-Max can also insert values into an NC-File while sending them, and this is the tip of the iceberg in terms of what it can do. Using regular expression you can perform incredibly powerful and useful manipulation of the gcode file. A typical example would be adding a statement that will be used in our next step, a value that can trigger an MDC event. Just look at all the options available to customize sending of files on DNC-Max:

Triggering Data Collection Events

When a file is being sent, we can also trigger updates within MDC. One example would be the active program being produced, normally this is either gathered via operator input or when available collected using an advanced network protocol. This data and any other relevant data which can create updates to information within MDC saving the operator from the time and potential for errors will greatly enhance the usefulness of a CIMCO data collection system. There are other better alternatives also to get this and much more information, directly from your MES or ERP system when the user clocks into the job. This is a typical scenario in a smart manufacturing facility and most of our customers take advantage of this approach today.

Why Manufacturing Data Management Integration is Important

Data management software like CIMCO MDM does a lot more than just provide paperless access to all manufacturing-related files. With a fully integrated solution it also provides other huge benefits:

- Receiving files back, comparing to existing files, and placing on import queue for review

- Paper trail of all sending, receiving of files

- Access to data collection data on a file by file basis

- A data collection world without a Swiss army knife is a sad place

The Power of an Import Queue

When all CNC equipment is connected to CIMCO DNC and seamlessly integrated with CIMCO Manufacturing Data Management or CIMCO NC-Base, you gain the ability to efficiently handle programs that have been edited or created on the shop floor. New files will automatically be placed into the import queue with full awareness of where they came from. Existing programs sent back will be automatically compared to the original version and if they have been altered the file will be placed on the import queue. If they have not been altered, the duplicate file will be deleted. This saves your programmers time reviewing only files that have changed. This is a strong argument for connecting networking machines to DNC and data management, but that will be a larger discussion for another day. Without touching these files your network-based data collection software will be completely unable to perform these duties and the reality is very few options like this exist and even fewer that are comprehensive in their capabilities.

ISO Compliance and Records of File Versions, Transmissions, and Updates

One of the top reasons customers ask us about CIMCO MDM is to trace all changes, transfers, updates, etc, of their manufacturing files. If you’re using a stand-alone MDC product, this is not possible or is cobbled together by different companies software. Real compliance without these integrated products often appears a lot like a dog chasing its own tail. It’s not fun for anyone involved.

Access to Real Cycle Time Data on an NC-file Basis

When you have MDC, DNC, and MDM all integrated into one facility, you have unique capabilities such as being able to access previous cycle time data for a given NC program. By creating and utilizing a simple report you can query all the previous cycle time data for a given nc program. You can include outliers such as longest, shortest and average cycle times for that part running the actual g-code in your environment. This information will be right at the fingertips of anyone with access to your MDM system.

MDM is like a Swiss Army Knife for CNC Manufacturing Automation

Due to it’s nature, CIMCO MDM is among the most powerful tools ever invented to manage and enhance a CNC-based manufacturing environment. We have now stepped way beyond data collection and communications into a world of workflows, automation, and integrations with 3rd party applications that are incredibly flexible. A world where tool pre-setters, ERP/MRP software, databases, and business intelligence software can find a powerful ally in the pursuit of Industry 4.0/Smart Factory objectives. For these reasons, MDM has become our go-to tool here at Managed Solutions to solve our customers most demanding requirements. If someone is telling you something can’t be done, maybe they can’t do it but there is a good chance that with CIMCO MDM, we can.

Signals from Legacy Equipment

Sometimes DPRNT and/or network protocols are not enough, such as in the case of manual equipment, there needs to be another option. Many MDC providers do not offer the ability to interface with just about any piece of equipment. CIMCO MDC does using a variety of methods including an API, but for this article, we’ll focus on hardware-based signals. Normally our customers are seeking cycle time and part counts from their equipment, even manual machines. With the flexibility provided by CIMCO we can interface with legacy equipment by using hardware signals, typically relays or signal lights, to update cycle time and part counts.

Questions to Ask Potential MDC Providers

We’ve covered a lot of ground, hopefully, if you are still reading this we’ve provided some valuable points for your consideration. Certainly, it is our job to point out the advantages of CIMCO Software and our services, but this is also a PSA to help customers get the most out of their manufacturing environment whether they do business with us, a competitor, or a CIMCO dealer in another part of the world. The most important issue is when pursuing Industry 4.0/Smart Factories or Machine Data Collection, be sure you are casting a broad net in terms of what you take into account. Don’t settle, and ask the tough questions, this will keep all the service and product providers honest and lead to a better end result for manufacturers. Here are some things you might consider asking a potential MDC provider:

- Does your company offer DNC Communications Software?

- Is it your own product?

- How does it integrate with your data collection platform?

- Does it offer an API for third-party integration?

- How do you collect data from RS-232 based machines?

- How do you avoid my operators having to input a lot of data such as the program number, job number, etc?

- Does your DNC add value to the MDC software, if so, how?

- Does your company offer a data management product?

- Is it your own product?

- How does it integrate with your other products?

- How does it integrate with third-party applications?

- What customization options are available for it?

- How do you handle manual machines that do not have RS-232/DPRNT support or Network support such as FANUC FOCAS, Haas M-Net, MT-Connect, etc?

These are just a few things for your consideration. Hopefully this article has helped avoid stranding you on an isolated technology island where you will be forced to cobble together numerous products made by different companies to meet your automation goals.