Dynamic Lists and Import Features.

In part 1 of this series, we went over setting up the MDM configuration, copying the chooks over, and customizing the ribbon in Mastercam to add the CIMCO buttons to it. As promised in the first article, we’ll cover the setup of the dynamic tool list and the actual process of performing the exchange between MDM and Mastercam.

Setting up the Dynamic Tool and Operation lists

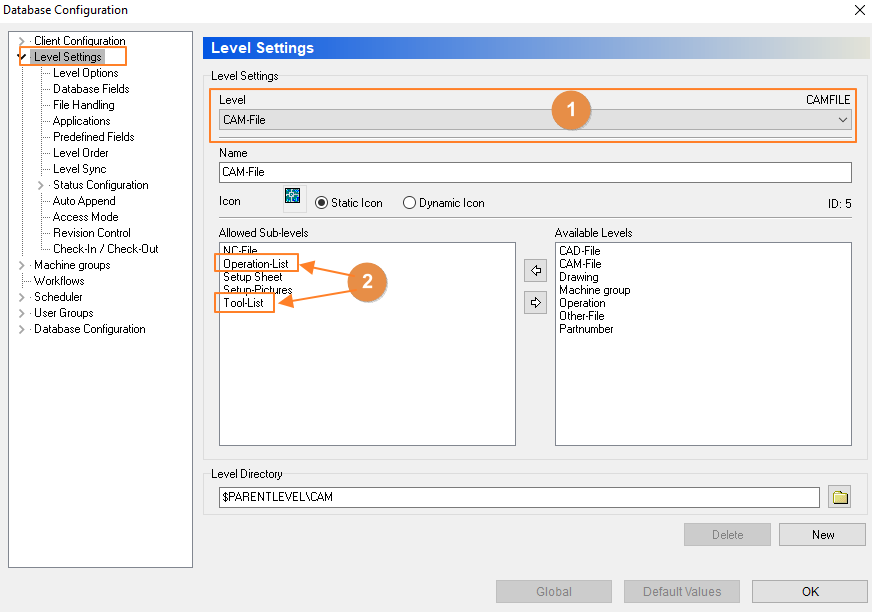

We need to make sure that the Operation-List and Tool-List are Allowed Sub-levels of the CAM-File level. In the MDM database configuration, go to ‘Level Settings’ in the left plane, choose the CAM-File level, and verify that the two levels are allowed.

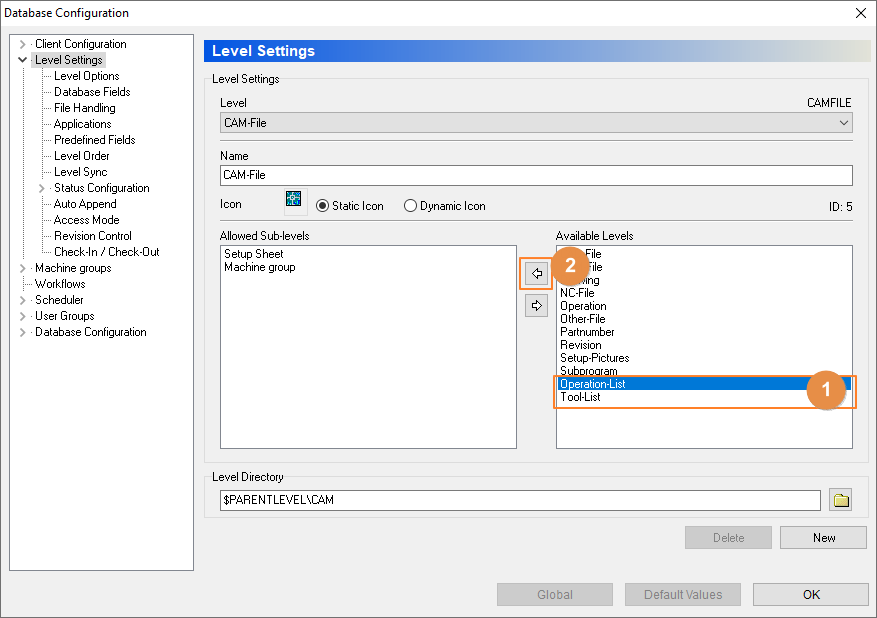

If not, select them on the right and click the arrow to move them from Available to Allowed.

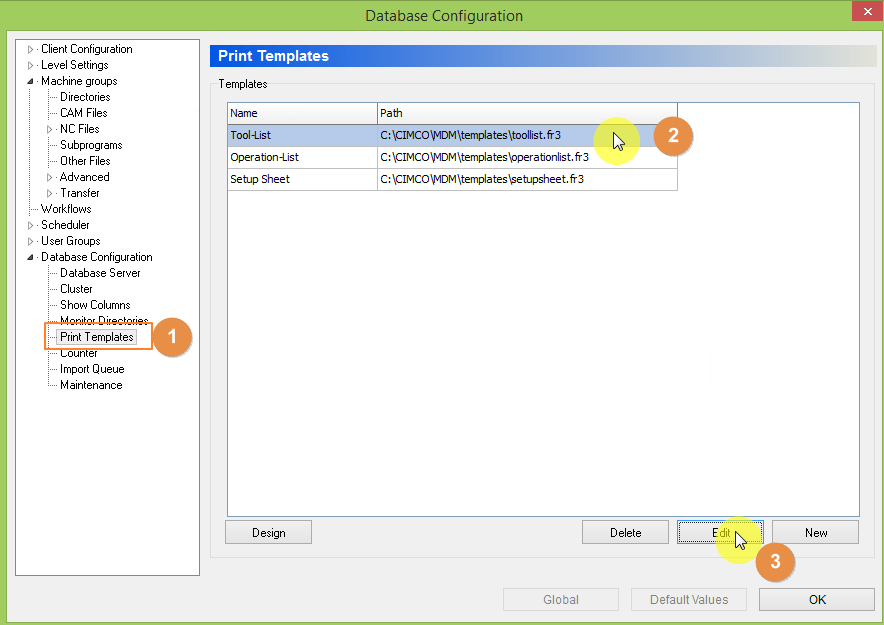

If we expand Database configuration in the left plane and select ‘Print Templates’, we can select our ‘Tool-List on the right and then click ‘Edit’.

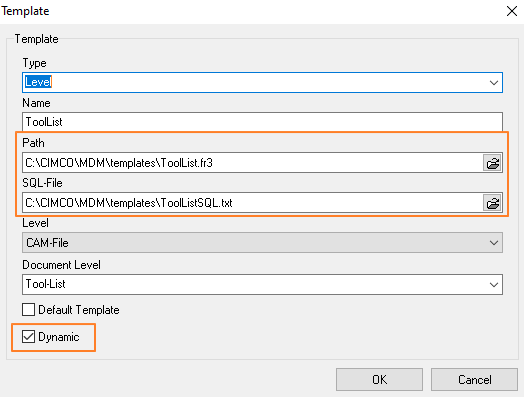

We want to make sure that the path information is filled in and that the box is checked for ‘Dynamic’. The image below shows the default file location for the tool list. We also want to make sure that the Operation-list is configured the same way.

Exchanging Tool Info and NC-code with MDM

In MDM:

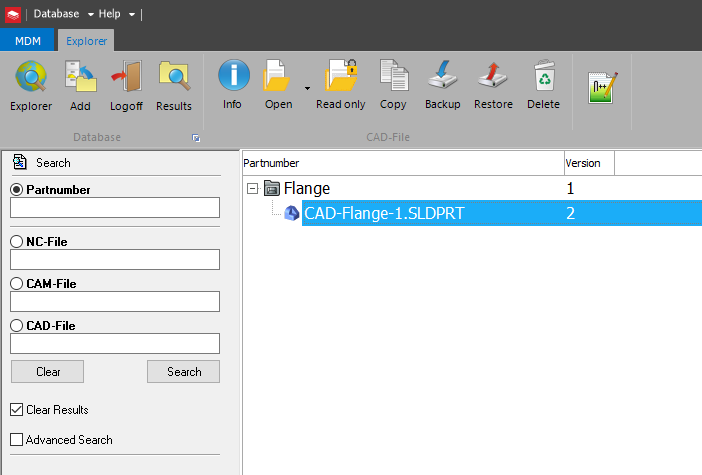

The first thing we want to do is select the file in MDM that we want to open in Mastercam.

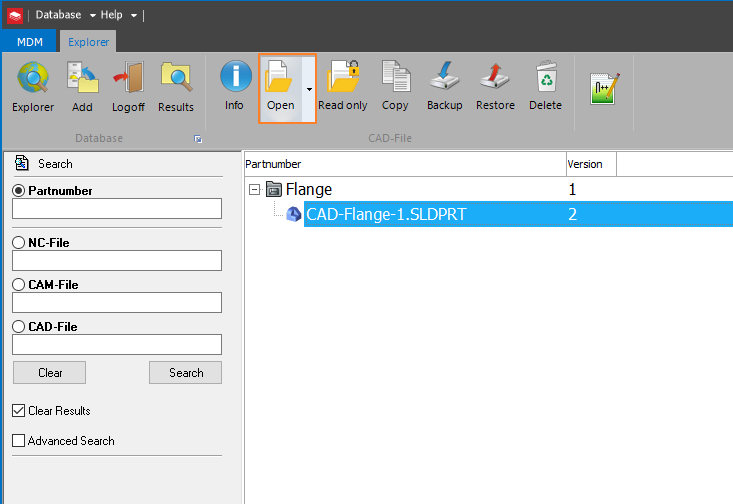

At this point, we want to click ‘Open’ from the ribbon.

You can also select the drop-down arrow to select an instance if Mastercam is already open.

In Mastercam:

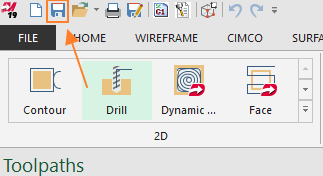

Now that we have a file opened that has operations added to it, we want to save it.

Notice that when we open a file in MDM, the software copies the file to the tmp folder from the database for us to work with.

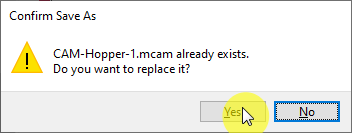

When we click on save, we will get a pop-up showing that the file already exists. We want to click ‘Yes’ to replace the existing file.

Now is a good time for us to generate NC code in Mastercam by clicking the button in the toolpath manager.

Click the check box in the Post processing window to generate code.

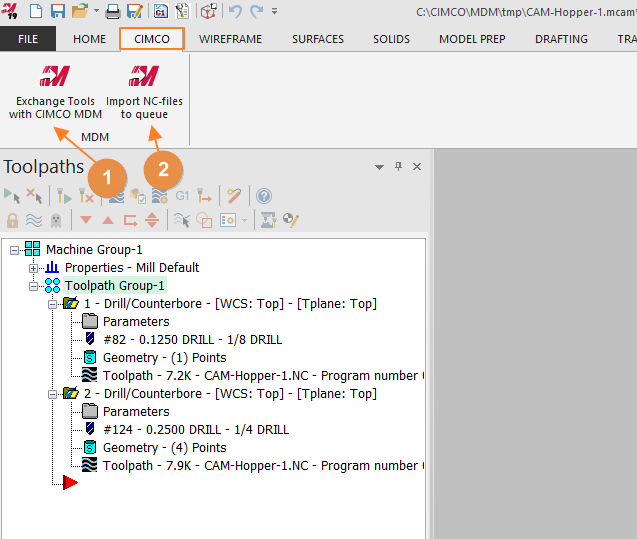

Now that we have NC code, we want to go to the CIMCO tab (we created it in part 1) in the ribbon and click ‘Exchange Tools’. Once it’s done generating images, click ‘Import NC-files’.

Back to MDM:

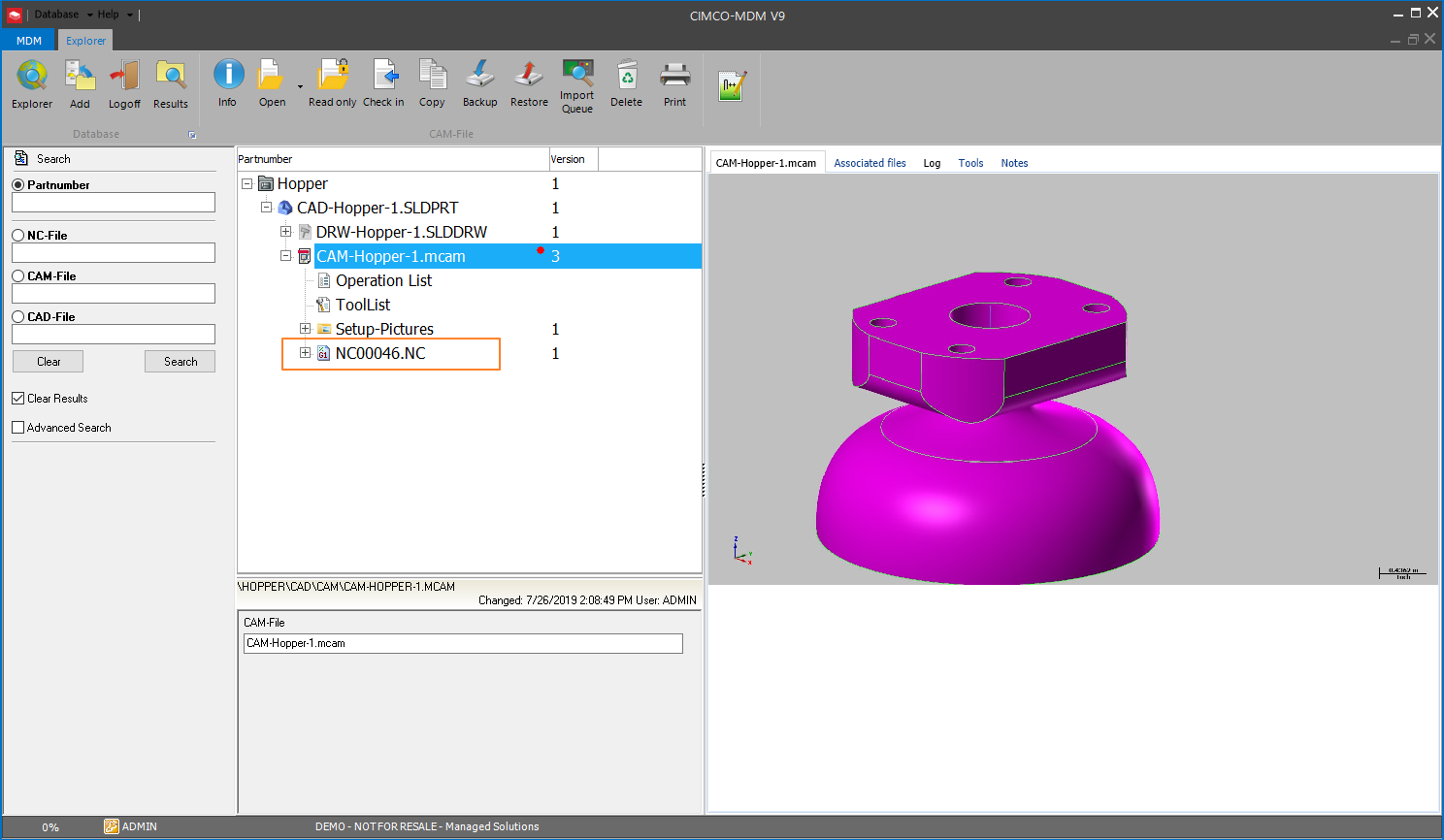

In the pop-up in MDM, we want to select a machine group and click ‘OK’. You will notice in the example that MDM is configured to generate a name for the NC-file. This is only one option. We can also use the original filename or designate one at this point.

Now we can see our newly added NC-file in MDM under our CAM-File level. We can also see a preview of the Mastercam file that is generated with the exchange.

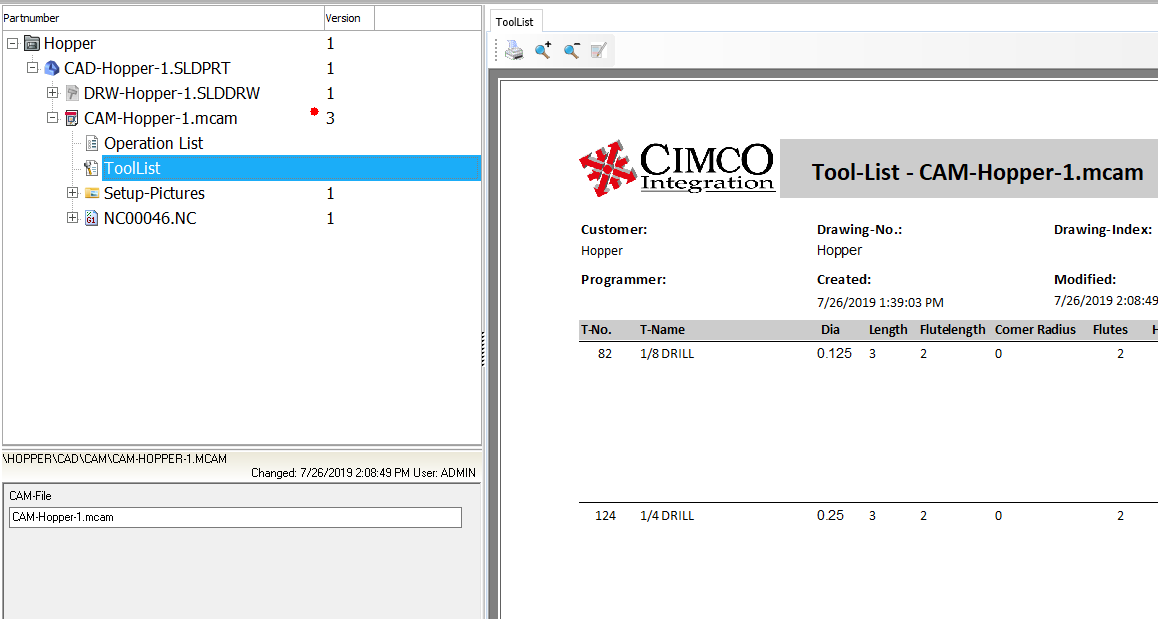

If we click on the Tool List, we can see that our dynamic form has updated to include the data that was passed over from Mastercam.

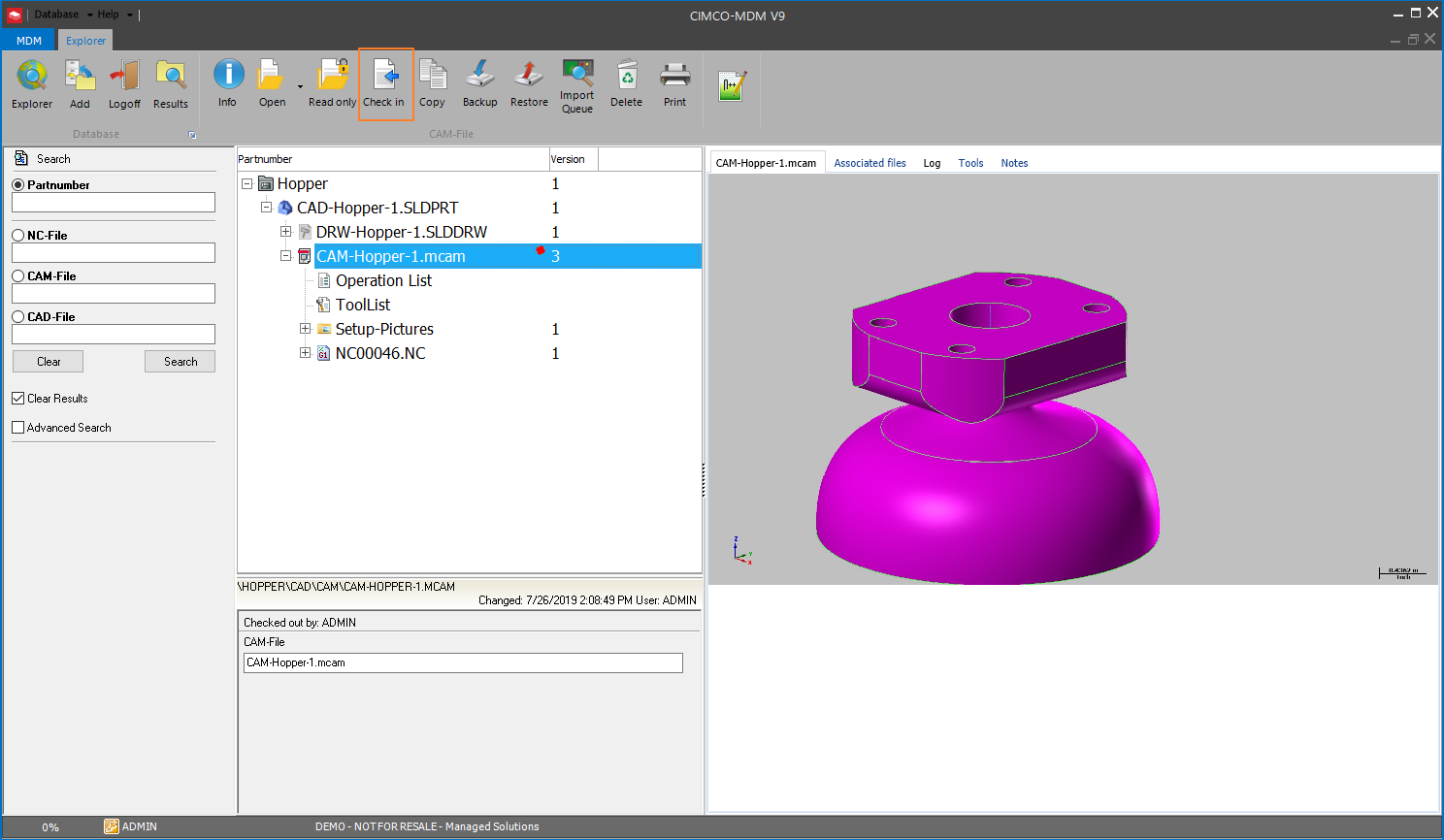

Now we need to check the file back into the database by clicking the ‘Check in’ button on the ribbon.

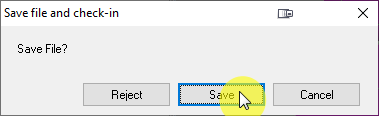

We still have the option to reject the changes to the file if we wanted too but you normally want to click ‘Save’ on the pop-up.

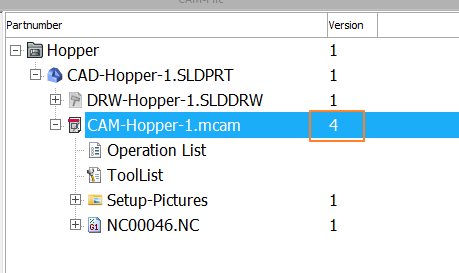

You can see now that the file is checked in that the version number has incremented because we saved the file back to the database.

That’s all there is to it

The data in the Operation list and Tool list will update automatically every time you do the tool exchange. These forms are also completely customizable, and we’ll go more in depth with them in part 3 of this series. They can be changed to include your company logo in addition to adding or removing data to fit your individual needs. They will remain in MDM where you can view and/or print them as necessary. If your shop has PCs at the machines, this has the added benefit of being a cost-saving opportunity because your operators don’t need to print these sheets to have access to them. This also guarantees they always have access to the latest version.

Let us know if you have any questions or leave a comment below.

What if the operators make a change to the program at the machine such as a feed rate or spindle speed? When this is brought back into CIMCO is there a way to automatically update the Mastercam file with those changes?

Hi Eric, Joe with Shopware here. Unfortunately, that has not been implemented into MDM. Currently, MDM has no way to track what speeds and feeds are associated with specific operations in Mastercam. Interesting thought, though!