In this article we’ll review some common and advanced usage of barcode readers with CIMCO Software.

The role of barcode readers in Smart Manufacturing

Barcode readers provide for quick and accurate data acquisition, limiting errors from data entry. CIMCO’s use of barcode readers has evolved over the years from very basic functions to intricate and powerful multi-step schemes. Barcodes can be affixed anywhere, even directly printed, etched or otherwise transposed on to individual parts providing precise identification.

Which CIMCO products can be interfaced using a barcode reader?

- CIMCO DNC-Max (Server/Communications)

- CIMCO MDC-Max (Data Collection – OEE, Tracking, Visibility)

- CIMCO MDM (Manufacturing Data Management – paperless manufacturing, revision control, automation)

Note: CIMCO does not charge for barcode ports, so if you have any of the products covered here, you are already able to use barcode readers without paying any additional licensing fees. The main criteria is the barcode reader has to present itself as a COM port, which is common in industrial and smart manufacturing environments.

Now lets break down how the barcode readers are used in each product.

How are barcode readers used in CIMCO DNC-Max?

Think of CIMCO DNC-Max as an Enterprise Server for all things communications and data collection. It grew into that role after a long tenure as DNC Communications software. DNC has been necessary to deliver programs to RS-232 based CNC machines since it became available decades ago. As an Enterprise Server DNC Max has since evolved to support many specialized protocols for both serial and network communications. It also had the ability to interface a barcode reader for use by either DNC or MDC.

With DNC-Max barcode readers are most commonly used to perform remote request of CNC programs from the shop floor. Barcode labels affixed to documents (normally shop routers/work orders) are scanned and DNC Max looks up the program number referenced. If available, DNC-Max sends the file.

This is not good enough for people on an Industry 4.0 journey. At a minimum, they should use NC-Base, or MDM to provide higher assurance that only the correct/approved file will be transferred. Some users get around this requirement by strictly managing folders, we find this approach to be problematic due to limitations of the windows file system. You can learn more about why windows alone is not a great solution in our article You may need data management if.

How are barcode readers used in CIMCO MDC-Max?

CIMCO MDC-Max is a data processing engine for measuring machine productivity. Simple KPIs such as optimization (spindle uptime) are entry-level implementations and the limits are really subject only to the creativity of the implementation team and depth of desired outcomes.

For MDC-Max barcodes are most often used to manage job start/stops, operator logins, enter scrap and downtime reasons. When implementing MDC, we prefer to trigger job and operator logins, part numbers, etc, off of the customers’ MES or MRP system. If this is not possible, or desired (though we can’t imagine why!) the barcode readers can be used to ensure accuracy and limit errors so that the data being collected is accurate.

How are barcode readers used in CIMCO MDM?

CIMCO MDM is a comprehensive and flexible data management system for smart manufacturing. It is not necessarily specific to CNC environments, but it provides several big advantages for environments employing CNC machines. Those advantages include the ability to integrate with CAM software to generate Tool Lists, Setup Sheets, and Operation lists with supported CAM products. It also provides very comprehensive directory monitoring, which is typically used to compare programs coming back from production to see if they should be reviewed.

The purpose of this review is to see if there are good changes (improvements) so the standard program can be updated and those improvements can save time/improve quality in the future when that operation is run again. This is referred to as an “Import Queue”. Import queues are much simpler to manage since only changed files show up to be reviewed and you choose who is able to review them, too. Try doing that with a windows file system.

In addition to the strong position in CNC applications, there are also advanced capabilities such as Workflows, Status & Access modes (great for programs under revision that you do not want used in the production environment!) and you guessed it, barcode capabilities.

Barcode readers can be connected to a local any windows computer running the MDM client, or on the MDM server over the network using a network to serial device such as a Moxa NPort.

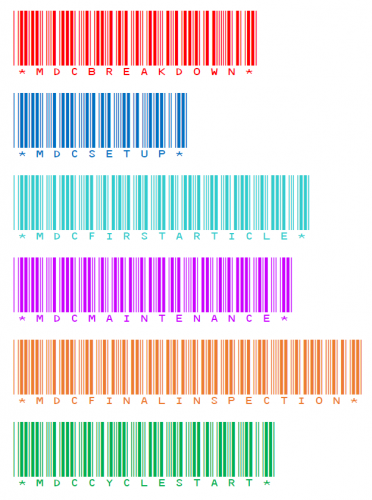

CIMCO MDM barcode integration allows for “barcode schemes”. These can be single or multi-step barcode routines.

Example single step routines:

Example single step routines:

- Transfer (approved only) program(s) to a CNC

- Send an MDC Message such as a downtime reason (pictured)

- Start a Workflow

- Send a result to a workstation (Client)

As long as each barcode is unique, you can create as many of these as you need across all your departments.

Example multiple-step routines:

- Conditional delivery of program(s) to a CNC

- Integrate barcode steps and other triggers (MDC Messages – see pictured)

- Make complicated things simple for your users

Multiple-step routines are very powerful, and our customers have used them to do things such as validate the correct fixture and program combination is in use. While recently speaking with a customer that had used what is our most complex (but easy to use!) scheme, they were able to eliminate machine crashes and make operators job of easily operating complex multi-table machines easier by only delivering these programs when the proper sequence/criteria had been followed.

CIMCO Software provides un-precedented flexibility in smart manufacturing projects. This is largely due to their long term experience with communications related to CNC equipment. This experience, the broad scope of capabilities, and large Solution Provider network provide strategic advantages that Industry 4.0/Smart Manufacturing initiatives truly need.

We’ll be sharing more on that flexibility in the future here on the blog. So please do not forget to Sign up for both blog updates, and the Five-Minute Gemba Bi-weekly for more on that.