You may already know that CIMCO DNC-Max provides end-to-end functionality designed to make every aspect of CNC communications more reliable and efficient. What you may not know is that to meet the demands in the marketplace for an open and scalable solution CIMCO also offers a Application Programming Interface (API) and remote control application to give users the ability to get more out of the system.

DNC-MAX Remote Control Application

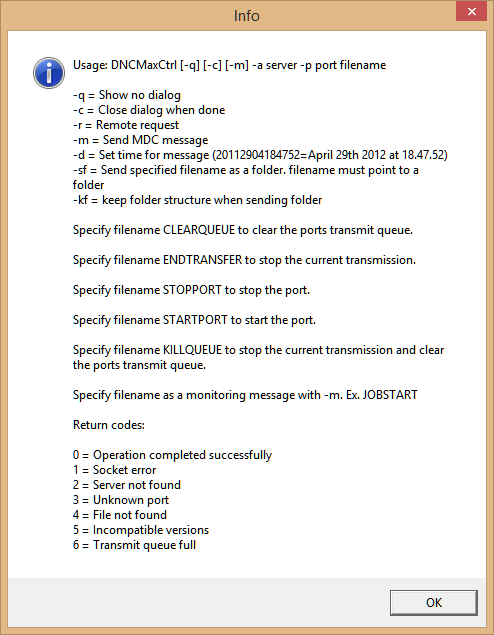

Included with DNC-Max is the remote control application C:\CIMCO\DNCMax7\DNCMaxCtrl.exe. This is a command line program that can be used instead of the DNC-Max client application. Here are the available parameters for this utility (as of version 7.55.31).:

DNC-MAX Application Programming Interface

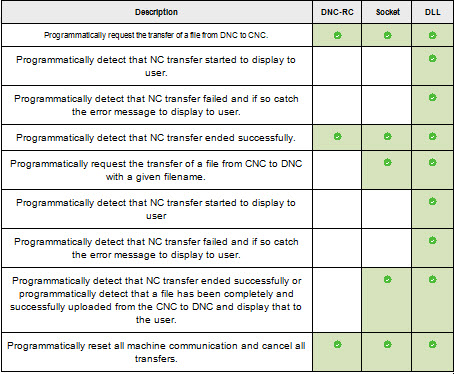

If you are writing an application that needs to use DNC-Max there is also an API that gives more options than using the remote control application. The API documentation can be supplied on request to CIMCO. Feel free to contacts us to make a formal request on your behalf.

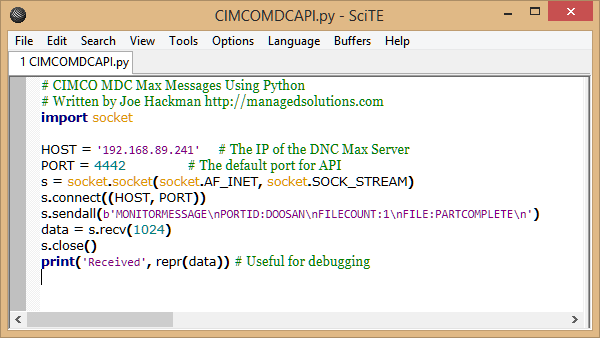

Example using a TCP String Sent using Python 3

Python is an incredibly useful programming language. It is frequently “glue” for some of our projects and customizations of CIMCO Software. In this example we are using Python to send a string to CIMCO DNC max to add a MDC message. This is actually bypassing the DNCMaxCtrl.exe and acting directly over TCP/IP which may be useful in some cases.

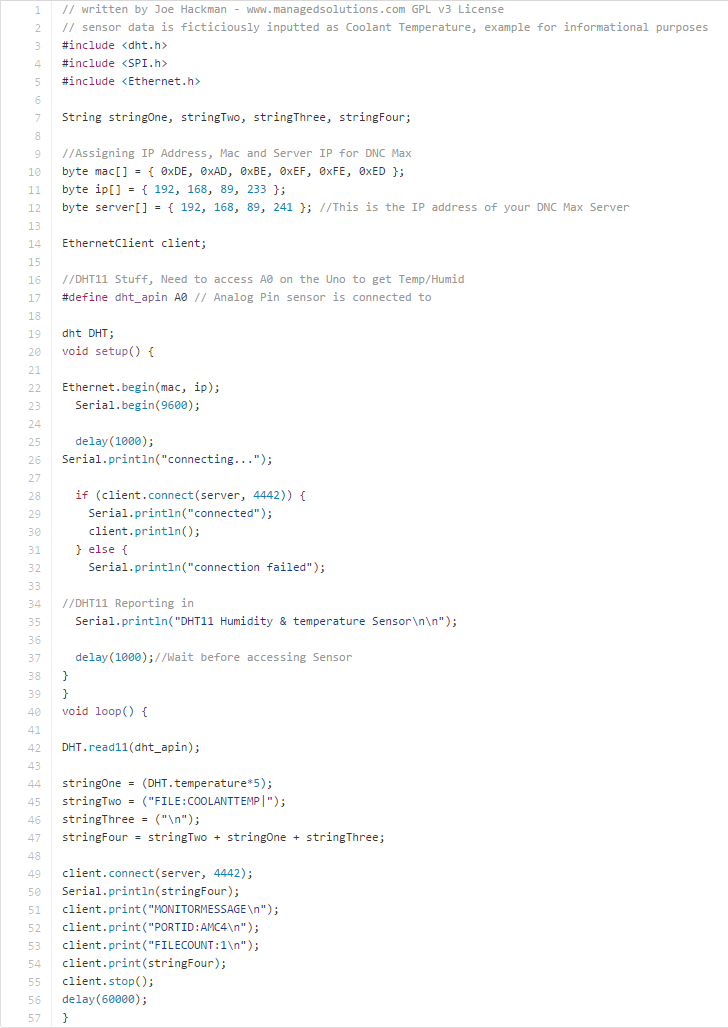

Example sending analog sensor data from an Arduino

Arduino, Raspberry Pi and other micro-controllers/computers are useful devices for prototyping advanced automation or implementing non-mission critical features in your environment. In this example we use a Arduino to read the input from an analog temperature/humidity sensor (DHT11) and present the data as if it were the coolant temperature of a CNC Machine.

Here is the resulting temperature reading in our demo system with custom values added for Coolant Temp as well as a CT alert button for over temp conditions.

Video not displaying? Try here.

If you are still reading this page, you probably like to tinker like to come up with creative ways to improve manufacturing environments. We’d love to hear about your small and big dreams using technology and creativity to improve your business. If you are trying to do something and need some “glue” to tie everything together, you came to the right place. We’re not big on painting by the numbers, it’s fun to dig in and create new innovative solutions to real world problems. Let’s talk!

Hi

Thank for you.

I have a small lathe machine that I want to control that with Arduino

I used powermill 2019 and I want to use CIMCO to send the Gcode to the Arduino and run the machine.

but I don’t know how to connect CIMCO to Arduino and programming them.

can you help me with this?

Hello Hamed. If the Arduino is setup for RS-232 data reception, it would work no differently than any other CNC. Since this is uncharted territory, would need to know more about how that is configured. From our side, it wouldn’t be an issue as long as the Arduino could accept the data via a COM port/RS-232 and store it or run it directly (e.g. drip feed).