As you might have guessed, there is no magic box for Industry 4.0. It is and will be a concept like True North in the Toyota Production System – a journey, not a destination.

Along the way, we’ll understand that connecting various systems is hard work, and many unique challenges will be faced. We have legacy platforms, duplicate/conflicting standards, niche vendors, proprietary systems, hardware, and software. Due to this reality, we must get as good at this journey as Toyota did with TPS to truly be Industry 4.0 practitioners.

What is Industry 4.0, and where did it come from?

Industry 4 or I4 was a project to promote the computerization of manufacturing promoted by the German government in 2011. The phrase “Fourth Industrial Revolution” was introduced in 2015 by Klaus Schwab of the World Economic Forum via an article in Foreign Affairs. Defined on Wikipedia as:

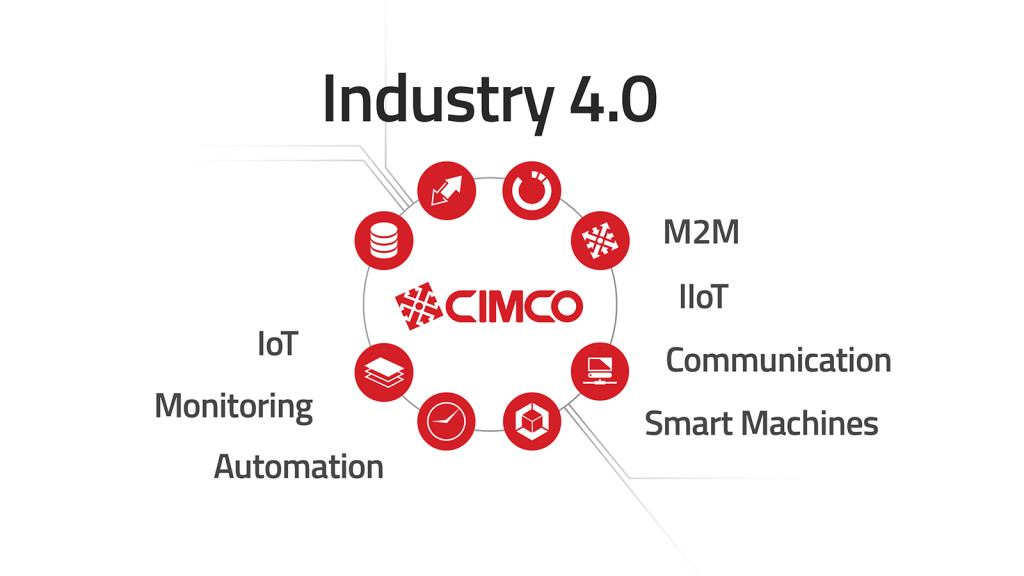

The Fourth Industrial Revolution (or Industry 4.0) is the ongoing transformation of traditional manufacturing and industrial practices combined with the latest smart technology. This primarily focuses on the use of large-scale machine to machine communication (M2M) and Internet of Things (IoT) deployments to provide increased automation, improved communication and self-monitoring, as well as smart machines that can analyze and diagnose issues without the need for human intervention.

In this series, I will focus on the bottlenecks that sit between current systems and the desired outcomes of Industry 4.0. We’ll all need to prepare for and break those down to get very far in our journey:

- Machine to Machine (M2M) Communication

- Internet of Things (IoT) or Industrial Internet of Things (IIoT)

- Increased Automation

- Improved Communication

- Self-Monitoring

- Smart Machines

Over the next several weeks, I will share the role that CIMCO Software and CIMCO Solution Providers like Managed Solutions play in this journey. CIMCO Software plays a unique and valuable role as Middleware.

Google dictionary defines middleware as:

Software that acts like a bridge between an operating system or database and applications, especially on a network.

Middleware.org (circa 2008) has an even better definition:

Middleware is computer software that provides services to software applications beyond those available from the operating system. It can be described as “software glue”.

To say we have seen a rise in the needs for middleware in the evolving smart manufacturing/Industry 4.0 landscape would be an understatement – software glue is in short supply. This may be due to how easy it is for companies to get tunnel vision and imagine a world where people only use their products and nothing else.

The reality is that technology has to be built in real-time to deal with each environment’s unique challenges. This is no longer a shadowy, mysterious world. This is every day with numerous companies seeking to build the next generation of their operations. We live in this world every day, and in so many ways have since the company started in 1997. We and our CIMCO Solution Provider counterparts around the globe are unafraid of this bold new world.

Thank you for reading the first installment of a multi-part series on CIMCO Software as Industry 4.0 Middleware. In the next edition, learn about CIMCO DNC-Max role as Industry 4.0 Middleware.

[…] including CIMCO Manufacturing Data Management and Machine Data Collection. With CIMCO Software as Industry 4.0 middleware and Managed Solutions integration expertise this can help you achieve better […]

[…] CIMCO’s robust suite of tools allows us to offer advanced manufacturing data management, real-time data collection, program simulation, and an open platform to integrate with. […]

[…] For more on how CIMCO products support system interoperability, check out our articles on CIMCO Software as Industry 4.0 Middleware and CIMCO DNC-Max’s Role as Industry 4.0 Middleware. CIMCO products integration capabilities are […]

[…] also actionable in real time. With the native strengths of CIMCO Machine Data Collection (MDC) as middleware for Industry 4.0, UNS is possible, enabling seamless integration and contextualization of data from diverse systems. […]