The Professional Management Tool for Organizing and Making Production Documents Available

CIMCO MDM is a paperless manufacturing data management system that helps you manage, control, and securely store CAD/CAM files, NC programs, setup sheets, tool lists, quality documents, images, and any other production-related data.

Meeting your high goals in productivity and quality today and in the future requires a constant focus on optimizing your company’s processes and workflows. A strategy for managing information needs to play a central role in any company where getting the right information to the right people and equipment as efficiently as possible is crucial. CIMCO MDM is designed to be that central strategy—a transformative tool that not only organizes your production data but also streamlines your entire manufacturing process, eliminating the chaos of scattered documents and outdated paper records.

With CIMCO MDM, you can centralize all your production documents in one secure place on your network, ensuring that CNC programmers, machinists, and managers have instant access to the latest, approved files. This system handles user permissions, backups, restoration, and revision control, delivering all the functionality you’d expect from a modern data management system—and more. Whether you’re sending files directly to the shop floor in seconds or collaborating across teams, MDM enhances efficiency and reduces costly errors.

Key Features of CIMCO MDM

CIMCO MDM offers a robust set of features to improve your manufacturing workflow:

- Change Tracking: Maintain a clear audit trail of every file modification for accountability and compliance.

- Remote Request: Enable shop floor operators to request files from CNC machines, with only approved programs sent—preventing mistakes.

- Data Backup & Restoration: Safeguard critical data with automated backups and easy recovery options.

- Centralized Document Access: Access all files from one secure location, eliminating scattered or outdated records.

- Comments & Collaboration: Add notes directly to files, enhancing communication between teams.

- Machine Group Permissions: Restrict access to sensitive files, ensuring only authorized personnel can view or edit them.

- CAM Integrations: Automatically generate tool lists and setup sheets from your CAM system, saving time and reducing errors.

- Reporting & Automation: Streamline workflows with detailed reports and automated tasks.

- Alerting: Receive real-time notifications about critical changes or issues.

These features work together to create a system that not only manages data but actively boosts efficiency, reduces waste, and enhances productivity across your operation.

Working with CIMCO MDM

Structuring production data in CIMCO MDM is similar to organizing files in Microsoft Windows®, with folders containing sub-folders (referred to as Levels in MDM). However, MDM goes further by allowing you to configure permissions and restrictions on what files can be added to specific folders and who can access, modify, approve, or delete them. This ensures your folder structure is enforced and files are always in the right place.

For example, root folders can be set as Project folders, with only Part folders allowed beneath them. Part folders can be restricted to accept only specific file types, like CAD files, with CAM files nested below. You can even require additional metadata when creating new folders, making MDM a highly flexible and customizable tool for enforcing your information structure.

CAM Integration (Video)

Standalone or Integrated

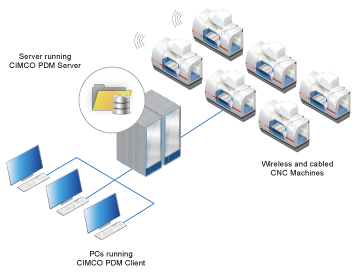

CIMCO MDM consists of a client and a server application. For smaller setups, both can run on a single standard Windows PC. For larger operations, the server can be installed on a dedicated machine, supporting an unlimited number of networked MDM clients. This scalability makes MDM ideal for any size of manufacturing operation, from small shops to large enterprises with multiple sites.

MDM integrates seamlessly with existing applications like ERP, MRP, or other file and database systems, ensuring a smooth flow of information across your operation. When paired with other CIMCO products—such as DNC-Max, MDC, and Edit—MDM delivers a multiplier effect, enhancing the capabilities of each tool for even greater efficiency. Read more about the multiplier effect.

Solve Your Toughest Manufacturing Challenges

CIMCO MDM tackles the root causes of inefficiency and error in manufacturing:

- Data Chaos: Eliminate scattered, unversioned, or lost files with a secure, centralized repository featuring revision control and backups.

- Access Control: Prevent unauthorized program use with machine group permissions and remote request features.

- Inefficient Workflows: Automate tasks like generating setup sheets or tool lists from CAM systems, reducing manual work.

- Lack of Traceability: Maintain an audit trail with change tracking and reporting for compliance and troubleshooting.

- Communication Gaps: Use comments and alerts to share critical information across teams, reducing downtime.

By addressing these challenges, CIMCO MDM creates a more controlled, efficient, and reliable manufacturing environment.

Other CIMCO MDM Resources/Documentation

- Adding Setup Pictures to MDM with a phone or tablet

- How to Enable Debug Log in MDM

- What’s new in MDM Version 9

- Eliminating Waste using CIMCO MDM

Ready to Try MDM for Yourself?

Don’t let disorganization hold you back. Discover how CIMCO MDM can streamline your operations, improve quality, and save time and money. Call or contact us to arrange a demo, or make a detailed inquiry online.