Lurking somewhere in your computer systems is data that in the future will be able to improve awareness, efficiency, and profitability at your company. This is possible by allowing you to more readily adapt data hungry technologies such as AI, machine learning and neural networks.1)The more data you have, the more accurate and useful these technologies are You’ve already made the investment through equipment purchases, employee efforts, software expenses and maintenance fees. Why not protect these valuable resources and plan for the future now?

Today we can’t order an Industry 4.0 starter box complete with machine learning and AI technology. That’s because such a box does not exist, nor is it likely to for many years. There is no doubt at some point the tools will get so good that re-processing legacy data will no longer be considered cutting edge. That should encourage us to take steps now to be much more ready, and competitive as those technological realizations come about.

Here are some suggested steps to prepare and protect your existing data resources while creating an environment to get the most out of it when these technologies mature:

- Assemble an appropriate team to prepare

- Identify Sources of Data worth Safeguarding

- Establish a Data Retention Initiative

- Perform (at a minimum!) annual Kaizen events around data and AI

Things to Consider When Assembling Your Team

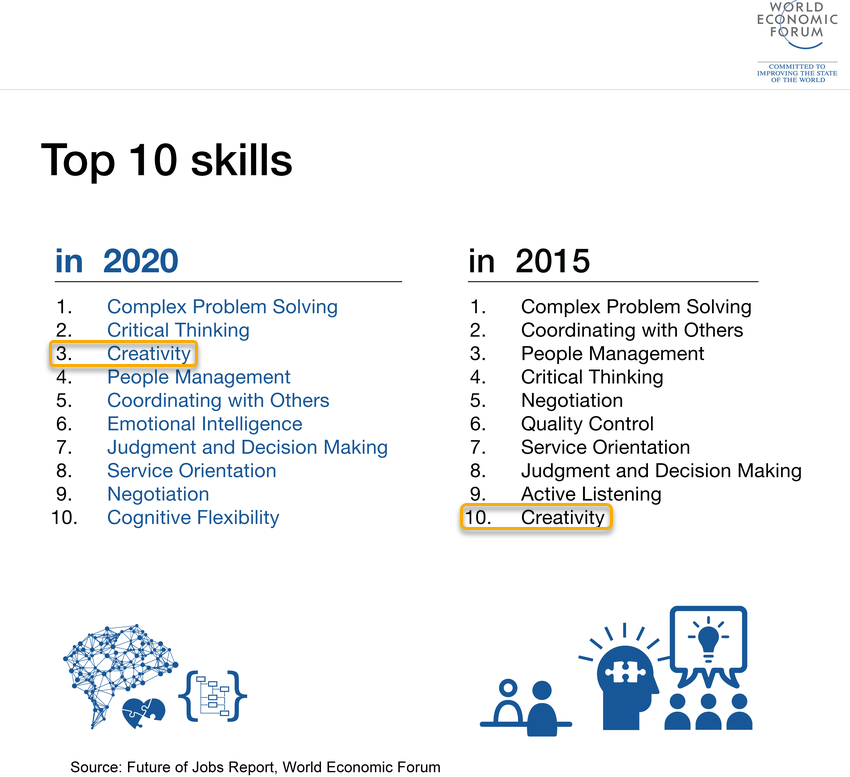

Perhaps the most critical portion of this process is to create a culture that is aware of these future possibilities and laying a proper foundation for success. With data resources this means you need to think about what existing components you have and how it might be used. This requires significant creativity, problem solving and critical thinking skills. Interestingly enough, creativity is projected to be among the most important skills driving the 4th Industrial Revolution. Looking back to a 2016 report by the World Economic Forum, much more emphasis was placed on creativity for 2020:

Ambition is somewhat obvious, but also overlooked in this list. We talk about that in “Thinking Big and Planning Small“.

The importance of creativity is the ability to think about what might be possible. You likely have a number of individuals with creativity and the other pertinent skills. Don’t forget the potential unsung heroes, building a diverse team with people closest to the respective roles is important.

Identify Sources of Data worth Safeguarding

To better describe how this might look, let’s consider a hypothetical small manufacturing company. This company has MES2)Manufacturing Execution System – used to track production on the shop or plant floor and ERP3)Enterprise Resource Planning – used to manage business processes systems that are at the heart of their business. These platforms have been in use for their entire six years in business, are well maintained, and used by every department.

Two years ago the company added some machine tools and a Machine Data Collection (MDC) platform. Unfortunately when they implemented the MDC platform, they did not integrate it with their ERP/MES system. Additionally since the MDC system was so hastily installed and was not provided necessary data to calculate OEE, the ability for operators to input downtime reasons, or anything else. It is isolated and just reading data directly off the machines (running/not running/part counters/alarms/etc). The lack of a link between the ERP/MES/MDC system makes it difficult to consolidate manual collection (MES, subjective) and automatic collection (MDC, automatic). This is really important to get quality efficiency and costing data. We go into that and other aspects of your hidden factory here and it might be a good idea to read that article too for more background.

Data for these applications is being stored on local servers in the company data center. In our current scenario your team may surmise that some kind of artificial intelligence could take the MES, ERP, and MDC data and mesh it together using some logical algorithms to figure out retro-actively determine things that would normally only be accessible to a fully integrated system such as:

- OEE4)Overall Equipment Effectiveness, an industry benchmark that takes into account performance, quality, and availability.

- Cycle Times

- Setup Time

- Tear-down Time

- Breakdown/Maintenance

- How accurate estimates were (Job Profitability)

- Actual lost time5)Say an operation was open for 4 hours on a given work center but the machine, setup and tear-down time only took 2 hours and 45 minutes without any logical reason for downtime or delays.

Imagine the story reality will tell about those 2 years (or more!) without any logical link. There would likely be some hard data to confirm much of what was suspected but absolutely some surprises. The resulting data would provide clarity for action and a rich environment for Kaizen events.

What else might be lurking around in unsuspected places?

You might also recognize that a spreadsheet containing seemingly unrelated data such as references mapping g-code file locations and names to customer part numbers may also be a worth while data point. For example it may result in more effectively determining traceability of a part by meshing timestamps of backed up g-code files with previously deciphered job data. Or perhaps log files from communications software may also further validate the results and fill in some blanks by showing a record of the file that was sent to the CNC to run the part and sent back after.

Get where we’re going with this? The possibilities are endless, and a little creativity can help identify the data that will make the most positive impact.

Bottom line, a deep dive and thorough brainstorming are essential to find data that could have a huge impact and net positive value for the company. Cast a broad net, most data is relatively small when compressed, storage is cheap, and it may be hard to tell the priceless data from the mundane.

Establishing a Data Retention Initiative

Your team has done an impressive analysis of what might be useful and provided a detailed list of resources to safeguard. Now it’s time to sit down with the IT team and figure out how to ensure a backup and data retention policy is in place. We’re going to skim over this step, but these are things your team may wish to consider when creating processes and validation steps for the data retention initiative:

- Confirm all needed data is being backed up. (Especially anything that might be in atypical areas of the network such as programming or engineering computers.)

- If cloud hosted systems are being used, account for periodic downloads of that data also.

- Confirm that all of the data has an unlimited shelf life.6)e.g. a permanent retention policy

Kaizen Events around Data and AI

Kaizen7)Japanese word kaizen means “change for better” often associated with Lean Manufacturing and the Toyota Production System events should be scheduled and executed to evaluate not just any new potential data sources, but also to evaluate how viable emerging and established technologies have become. Many companies now have continuous improvement engineers, this would be something they could take on as part of their efforts. Through these events you can implement changes and enhancements that make sense based on what is available at the time. Your data will be currency you can spend to catapult your business to new levels in the future, what to do will become more and more obvious as time goes on. After all, you will be ahead of the curve in both mindset and data.

Not sure where to start or have questions? We can help.

Please see also Unified Name Space (UNS): Future-Proofing Manufacturing for the AI Era, to learn more on future proofing your data.

References

| ↑1 | The more data you have, the more accurate and useful these technologies are |

|---|---|

| ↑2 | Manufacturing Execution System – used to track production on the shop or plant floor |

| ↑3 | Enterprise Resource Planning – used to manage business processes |

| ↑4 | Overall Equipment Effectiveness, an industry benchmark that takes into account performance, quality, and availability. |

| ↑5 | Say an operation was open for 4 hours on a given work center but the machine, setup and tear-down time only took 2 hours and 45 minutes without any logical reason for downtime or delays. |

| ↑6 | e.g. a permanent retention policy |

| ↑7 | Japanese word kaizen means “change for better” often associated with Lean Manufacturing and the Toyota Production System |

[…] […]