One way to help digitally transform manufacturing companies is to implement enhanced traceability. This can be useful to ensure that required tolerances and procedures have been followed, as well as provide additional data related to the manufacture of a given component or product. For example a company may need to provide documentation to show that a part was within all tolerances, machined using a correct part and passed all QC steps as required.

This could be particularly important if a part fails or is involved in an incident where critical operations or people are harmed. In these cases more data is better and more likely to help protect the manufacturer from potential liability. While most companies have procedures in place that meet requirements, some methods being used today are fairly simple and limited. In response to the push to be smarter with data and systems (Industry 4.0), we’ve been looking at extending a good traceability platform to make it even better and easier to use.

Another advantage is enhanced traceability provides data that will be very useful for future analysis when/if parts do fail. One or more factors could be common to certain kinds of failures. Without comprehensive data, this is extremely difficult to determine. See also Data Is The Foundation For Artificial Intelligence And Machine Learning for more on that.

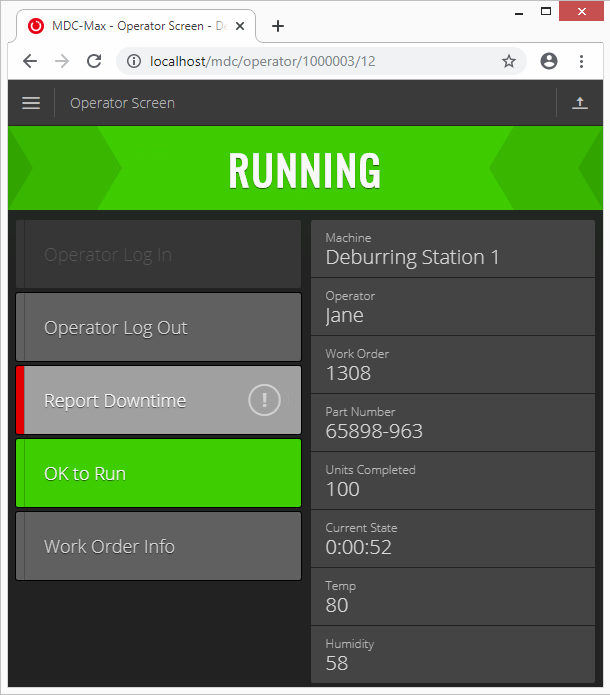

Now let’s imagine for a moment what different types of data might be useful to ensure optimal quality. Some materials and processes could be adversely affected by temperature and humidity, as such it would be good to have sensor data. Knowing the actual source documents and programs would also be extremely important, particularly for parts made with CNC machines. Knowing if a procedure was completed within a typical time or based on anticipated norms would also be an indicator of quality. Here are some example data points are possible using CIMCO Software products such as Machine Data Collection (MDC) and Manufacturing Data Management (MDM):

- Revision Info

- Drawing number

- Original CAM File

- NC File Version for all CNC Operations

- Cycle times for all Operations

- Operators for all Operations

- Feed/Spindle Overrides (CNC Operations)

- Setup, Inspection, Tear-down times

- Scrap Counts

- Rework

- Quality Documents

- Sensor Data (Such as temperature, humidity, vibration, really anything!)

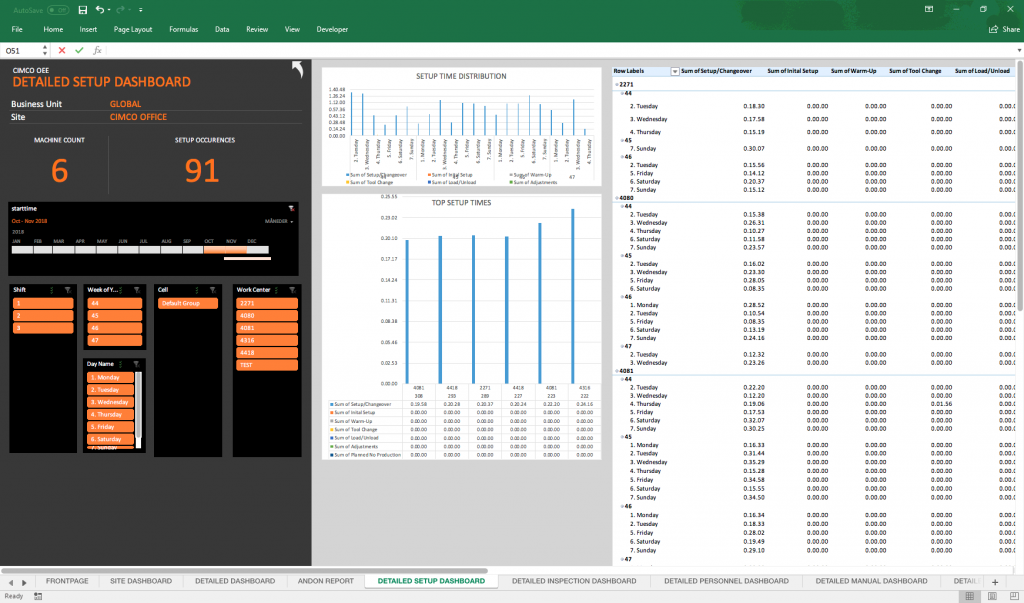

Once collected, this data can be accessed either directly through CIMCO products, or ideally, written to the company MRP/ERP/MES system. A report using Microsoft Excel (via ODBC) or more advanced tools such as Power BI, Tableau, etc. can be used, allowing your analysts to use the tools that they are most proficient with. This provides for fast lookup and very rapid assessment of all aspects of parts down to the individual serial number or batch of parts, depending on the need. This is made possible due to several factors:

- Open access to data (CIMCO Database Server)

- Having advanced data collection capabilities (MDC)

- Managing all production related documents including all revisions and tracking directly (MDM)

Below is a sample of MDC data being accessed via Excel today by many of our MDC customers.

Now let’s imagine this data being accessed in a single report based on a serial number, work order, or batch number, easily. Imagine being able to see all operations, cycle times, as well as any variances and sensor data. Real data, not just data keyed into a terminal before and after an operation, see Five Methods to Measure Your Hidden Factory for more on collection methods. Imagine being able to also see exactly which NC programs, CAD drawings and CAM files had been used. How about viewing the actual CMM report? All that would be very useful for quickly validating a “normal” part.

Now for the fun news. We’ve been hard at work creating an actually proof of concept demonstrating this exact workflow using only CIMCO software!

In our traceability platform we provide tracking of the Work Order, Operation, Work Center, Operator along with sensor data, in this case environmental data, for both machining and other operations:

In the release version of this platform we will show reporting within the CIMCO Software via MDM and MDC, as well as using an external system to access the information. The purpose of this exercise is to demonstrate what is possible so we can start looking at Industry 4.0 projects more ambitiously when CIMCO products are used.

Currently the finishing touches are being put on the system. Once completed we’ll be anxious to share it with you all. If you’d like to discuss this or similar endeavors, drop us a line or leave a comment below.

[…] may also be a worth while data point. For example it may result in more effectively determining traceability of a part by meshing timestamps of backed up g-code files with previously deciphered job data. Or […]